want to read about : Ice protection - INTRODUCTION

HOT AIR SYSTEM

|

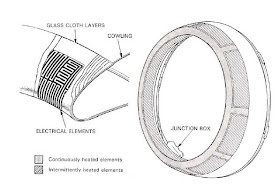

| Fig. 13-4 Electrical ice protection. |

6. The hot air for the anti-icing system is usually taken from the high pressure compressor stages. It is ducted through pressure regulating valves, to the parts requiring anti-icing. Spent air from the nose cowl anti-icing system may be exhausted into the compressor intake or vented overboard.

7. If the nose cone is anti-iced its hot air supply may be independent or integral with that of the nose cowl and compressor stators. For an independent system, the nose cone is usually anti-iced by a continuous unregulated supply of hot air via internal ducting from the compressor.

8. The pressure regulating valves are electrically actuated by manual selection, or automatically by signals from the aircraft ice detection system. The valves prevent excessive pressures being developed in the system, and act also as an economy device at the higher engine speeds by limiting the air offtake from the compressor, thus preventing an excessive loss in performance. The main valve may be manually locked in a pre-selected position prior to take-off in the event of a valve malfunction, prior to replacement.

No comments:

Post a Comment