want to read about : Starting and ignition - Hydraulic

IGNITION

18. High-energy (H.E.) ignition is used for starting all jet engines and a dual system is always fitted. Each system has an ignition unit connected to its own igniter plug, the two plugs being situated in different positions in the combustion system.

19. Each H.E. ignition unit receives a low voltage supply, controlled by the starting system electrical circuit, from the aircraft electrical system. The electrical energy is stored in the unit until, at a pre- determined value, the energy is dissipated as a high voltage, high amperage discharge across the igniter plug.

20. Ignition units are rated in 'joules' (one joule equals one watt per second). They are designed to give outputs which may vary according to require- ments. A high value output (e.g. twelve joule) is necessary to ensure that the engine will obtain a sat- isfactory relight at high altitudes and is sometimes necessary for starting. However, under certain flight conditions, such as icing or take-off in heavy rain or snow, it may be necessary to have the ignition system continuously operating to give an automatic relight should flame extinction occur. For this condition, a low value output (e.g. three to six joule) is preferred because it results in a longer life of the igniter plug and ignition unit. Consequently, to suit all engine operating conditions, a combined system giving a high and low value output is favoured. Such a system would consist of one unit emitting a high output to one igniter plug, and a second unit giving a low output to a second igniter plug. However, some ignition units are capable o! supplying both high and low outputs, the value being pre-selected asrequired.

21. An ignition unit may be supplied with direct current (D.C.) and operated by a trembler mechanism or a transistor chopper circuit, or supplied with alternating current (A.C.) and operated by a transformer. The operation of each type of unit is described in the subsequent paragraphs.

|

| Fig. 11-10 A D.C. trembler-operated ignition unit. |

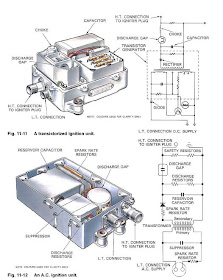

23. Operation of the transistorized ignition unit is similar to that of the D.C. trembler-operated unit, except that the trembler-unit is replaced by a transistor chopper circuit. A typical transistorized unit is shown in fig. 11-11;

such a unit has many advantages over the trembler-operated unit because it has no moving parts and gives a much longer operating life. The size of the transistorized unit is reduced and its weight is less than that of the trembler-operated unit.

|

| Fig. 11-11 A transistorized ignition unit. and Fig. 11-12 An A.C. ignition unit. |

24. The A.C. ignition unit, shown in fig, 11-12, receives an alternating current which is passed through a transformer and rectifier to charge a capacitor. When the voltage in the capacitor is equal to the breakdown value of a sealed discharge gap, the capacitor discharges the energy across the face of the igniter plug. Safety and discharge resistors arefitted as in the trembler-operated unit.

|

| Fig. 11-13 An igniter plug. |

This ionizes the surface of the pellet to provide a low resistance path for the energy stored in the capacitor. The discharge takes the form of a high intensity flashover from the electrode to the body and only requires a potential difference of approximately 2000 volts for operation.

26. The normal spark rate of a typical ignition system is between 60 and 100 sparks per minute. Periodic replacement of the igniter plug is necessary due to the progressive erosion of the igniter electrodes caused by each discharge.

27. The igniter plug tip protrudes approximately 0.1 inch into the flame tube. During operation the spark penetrates a further 0.75 inch. The fuel mixture is ignited in the relatively stable boundary layer which then propagates throughout the combustion system.

This comment has been removed by the author.

ReplyDelete