Lift engines

|

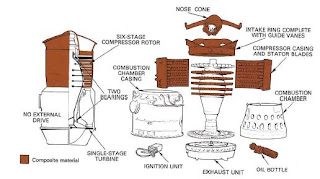

| Fig. 18-10 A lift-jet engine. |

14. Pure lift-jet engines have been developed with thrust/weight ratios of about 20:1 and still higher values are projected for the future. Weight is reduced by keeping the engine design simple and also by extensive use of composite materials (fig. 18-10). Because the engine is operated for only limited periods during specific flight conditions i.e. during take-off and landing, the fuel system can be simplified and a total loss oil system (Part 8), in which the used lubricating oil is ejected overboard, can be used.

|

| Fig. 18-11 Lift-fan engine configurations. |

15. Lift engines can be designed to operate in the vertical or horizontal position and a thrust deflecting nozzle fitted to provide some of the advantages of thrust vectoring. Alternatively, the engine may be mounted so that it can swivel through a large angle to provide thrust vectoring. The lift-jet engine will have an extremely hot, high velocity jet exhaust and to reduce ground erosion by the jet the normal exhaust nozzle may be replaced by a multi-lobe nozzle to increase the rate of mixing with the surrounding air.

16. The lift-fan engine is designed to reduce the jet exhaust velocity, to reduce ground erosion and allow operation from unprepared ground surfaces. It also reduces the jet noise significantly. A range of designoptions have been considered for this type of engine and some are shown on fig. 18-11.

No comments:

Post a Comment